LPG VanePump

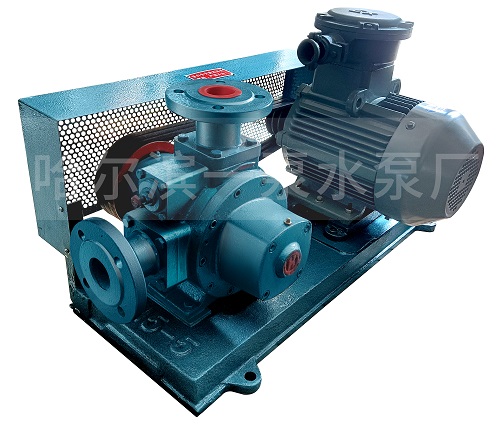

YQ Type Liquefied Gas Pump - Product Overview

The YQ type liquefied gas pump is a vane rotor pump primarily used for transporting volatile liquids such as liquefied petroleum gas (LPG), propane, ethane, liquid ammonia, isobutylene, and more. It provides greater flexibility for fluid transfer systems and fuel delivery vehicles. This series of products conforms to industry-standard flange dimensions.

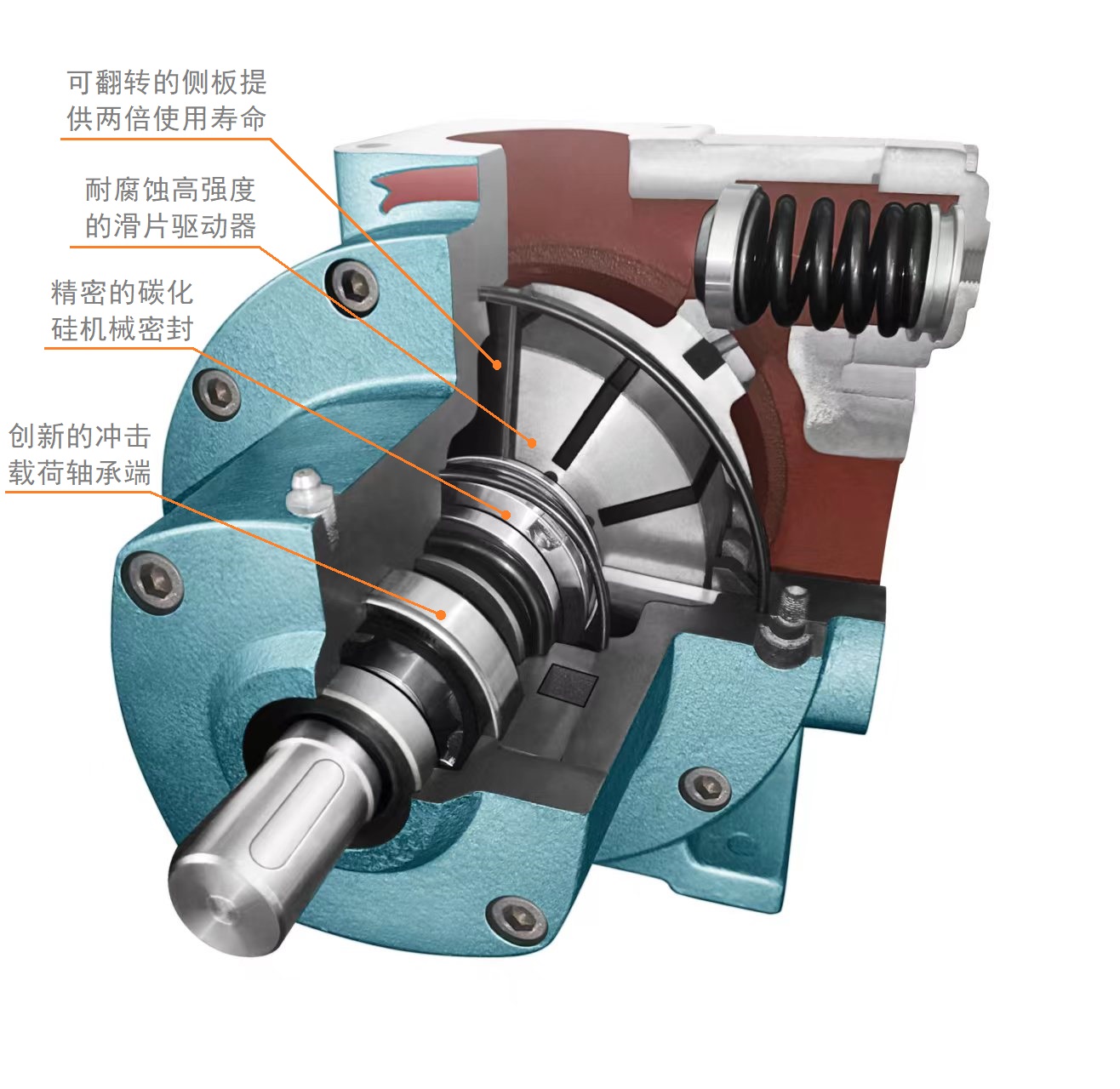

Easy Maintenance, Double the Lifespan

1. Independent Bearing Housing: Allows quick replacement of bearings and mechanical seals by removing only the outermost bearing cover.

2. Easy Disassembly: Removing one end cover enables quick replacement of side plates, vanes, seals, rotors, and other components.

3. Reversible Side Plates: Double-sided machined side plates can be flipped for use, reducing maintenance costs and quickly resuming production.

4. Highly Wear-Resistant Vanes: Made from non-metallic composite materials, ensuring low wear rates during long-term operation.

Multi-Media Compatible O-Rings

Special mechanical seals and matching O-rings developed by Harbin Pump are capable of pumping various refined petroleum products such as LPG, fuel oil, kerosene, diesel, etc., without needing to change seals.

Precision Rotor Vane Drive System

The unique design coupled with precision manufacturing techniques minimizes cavitation and noise, effectively reducing wear on vanes, rotors, and side plates.

Harbin Pump emphasizes material development and process iteration, offering products that provide exceptional performance and outstanding reliability.

Excellent Mechanical Design, Prolonging Service Life

The thrust absorption system of the YQ type pump consists of two needle bearings, each rated for 4,000 pounds. This patented design, located at each shaft end, protects the pump from dynamic impacts exerted by the drive system, reducing damage caused by axial forces.

Safety Valve Configuration

The YQ type liquefied gas pump is equipped with a manually adjustable safety valve. This valve serves as an internal bypass valve, providing internal pressure regulation. When the pump runs at full speed and the outlet pipeline is completely closed, the safety valve recirculates the fluid within the pump, relieving pressure. The greater the internal pressure, the more the safety valve opens. Additionally, the bypass opening pressure can be controlled by adjusting the bolt outside the safety valve.

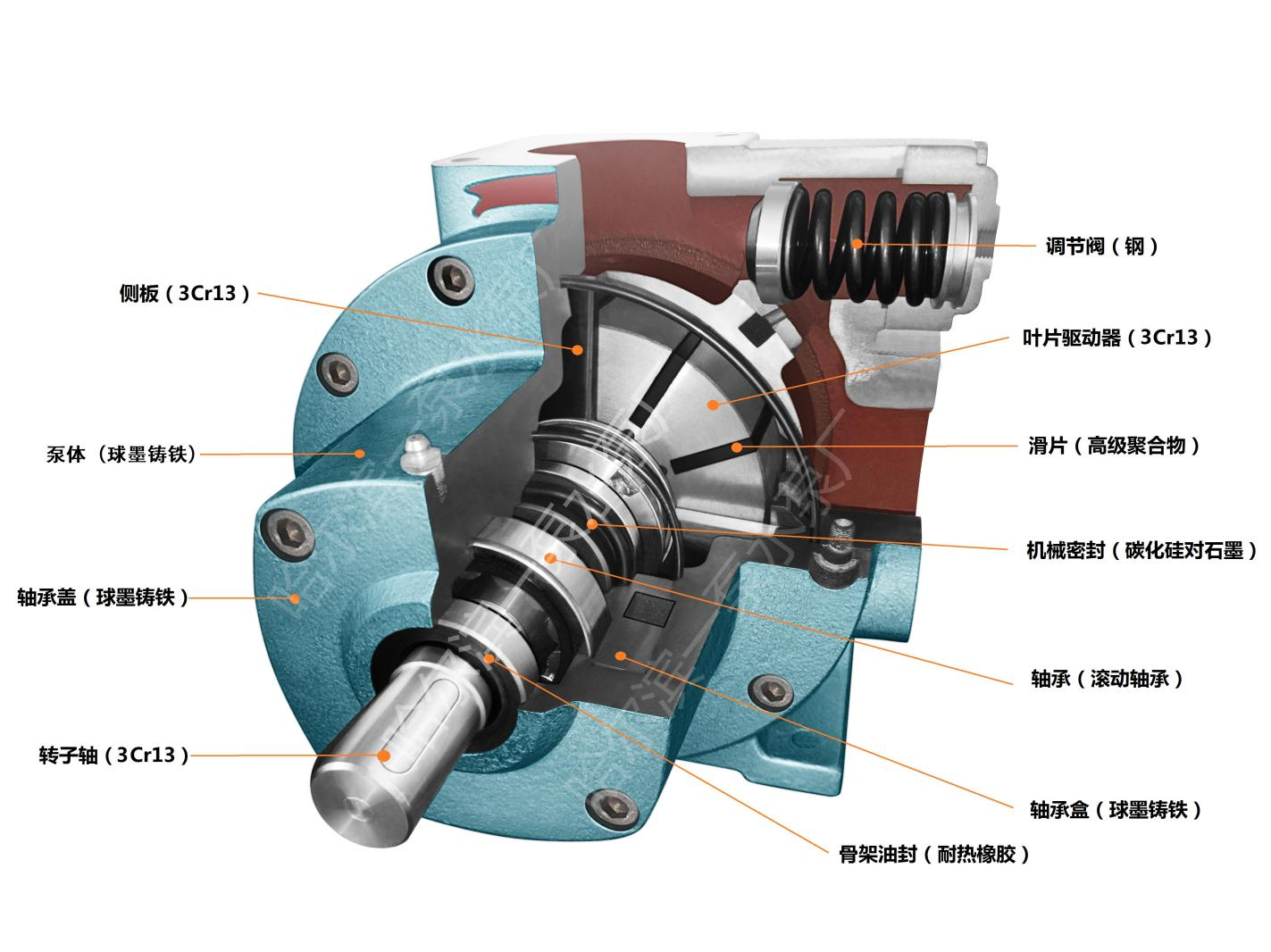

YQ Type Liquefied Gas Pump Structure Description

The YQ type pump is a vane rotor pump with numerous sliding friction surfaces, such as between the vane and rotor slot, vane and inner sleeve, rotor and side plate, and vane and side plate. To ensure high volumetric efficiency, the gaps between the sliding friction components must be minimal, necessitating high manufacturing precision. Thus, careful attention must be paid during assembly and disassembly of the pump.

- The pump rotates clockwise when viewed from the direction of the pulley.

- The pump's suction port is horizontal, and the discharge port is vertical.

Main Components

The main components of the pump include the pump body, inner sleeve, shaft, rotor, vanes, side plates, end covers, bearing housing, perforated cover, blind cover, mechanical seal, and safety valve.

- The pump body, end cover, bearing housing, perforated cover, and blind cover are made of ductile cast iron.

- The inner sleeve, fixed to the pump body with a key, is also made of ductile cast iron.

- The shaft and side plates are made of stainless steel.

- The rotor, positioned in the middle of the shaft, is made of ductile cast iron.

- Ten vanes made of advanced polymer are embedded in the rotor grooves.

- The working chamber is formed by the inner surface of the inner sleeve, the outer surface of the rotor, and the end surfaces of the two side plates. Since the inner sleeve line and the rotation center are not concentric, the vanes divide the working chamber into suction and discharge chambers during operation.

- During operation, the gaps between the rotor and the end surfaces of the two side plates can automatically adjust to be uniform. The end surfaces of the two side plates can be reversed for use if worn.